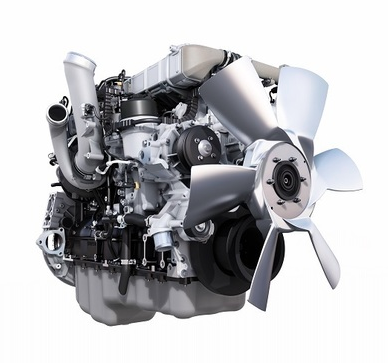

International Truck Launches A26, 12.4 Liter Engine

International Truck has launched the International® A26 engine, a powerful new 12.4-liter engine designed to provide greater uptime to the Class 8 market.

The A26 was developed through a new team of the industry powertrain engineers. The initiative pursued a fresh approach that emphasized simplicity over complexity and using only proven components to deliver industry-leading uptime.

“Project Alpha has fundamentally changed how we design diesel engines,” said Bill Kozek, president, Truck and Parts. “The International A26 has been designed to address the rigorous demands of Class 8 truck customers. It’s been tested to extremes and meets a demanding B10 design life standard for an unprecedented 1.2 million miles.”

Built from the proven MAN D26 engine crankcase, the A26 produces up to 475 horsepower and 1,750 lb.-ft. of torque from a design that’s 600-700 lbs. lighter than a traditional 15L big bore engine. Its components have been carefully engineered to deliver uncompromising uptime as well as class-leading fuel efficiency, reduced weight and quiet operation.

“The A26 was designed from the ground up to deliver industry-leading uptime, durability and reliability,” said Darren Gosbee, vice president, Advanced Engineering. “The A26 is as simple as a modern engine can be, and we’ve built uptime into every part of the development process, from design to calibration to testing.”

Utilizing a titanium compressor wheel with a simplified single-stage design, the A26 features a variable geometry turbocharger that reduces complexity and enhances reliability. Larger piston pins, connecting rods and bushings help optimize load distribution for enhanced durability, while smaller piston cooling jets increase oil pressure to improve lubrication, increasing oil change service intervals up to 70,000 miles.

At 2,299 pounds, the A26 is the lightest engine in its class. The A26 is 55 pounds lighter than the engine it replaces, and also enables an impressive 200 pounds of additional weight reduction in vehicle-mounted components. Its Compacted Graphite Iron (CGI) crankcase has greater strength and fatigue resistance than traditional gray iron. Composite valve covers and shot-peened aluminum flywheel housing help deliver impressive weight savings over traditional solutions.

The company says the engine can deliver up to five percent greater fuel economy, the A26 has a simplified air management system, featuring a new Variable Geometry Turbocharger.

The A26’s uniquely sculpted crankcase, which is isolated with the oil pan through a specially designed rubber gasket, absorbs vibration and reduces harshness for a quieter in-cab experience.

Category: Engines & Drivetrains, Featured