American Battery Solutions partners with Toshiba for fast charge and high-power battery applications

Enhances portfolio of battery system solutions for industrial and transportation applications

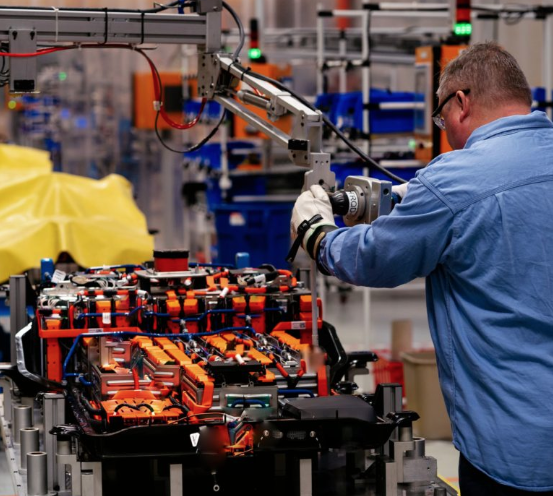

American Battery Solutions, Inc. (“ABS”), an advanced battery systems company, announced it is partnering with Toshiba International Corporation (“Toshiba”) to develop and deploy fast charge and high-power battery systems using lithium titanate (“LTO”) cells supplied by Toshiba for various industrial and transportation applications.

Under the MOU signed between the two companies, ABS and Toshiba will work jointly towards a master supply agreement for LTO cells, and will collaborate on the marketing efforts whereby, Toshiba will also bring customer opportunities to ABS and ABS will use Toshiba cells in those opportunities. In addition, Toshiba will be a preferred supplier of LTO cells for ABS.

ABS is developing a portfolio of battery modules and packs with Toshiba cells for rapid integration into custom battery systems to serve the growing industrial and transportation segments including:

- automated guided vehicles (“AGV”),

- industrial cranes,

- electric buses, as well as

- construction, agriculture and mining vehicles.

Customers in these segments will benefit from high up-time of equipment thanks to ultra-fast charging capability as well as ultra-long cycle life.

ABS sees opportunities for LTO-based solutions in some of the industrial segments where our tailored solutions can bring optimized total cost of ownership and increased productivity, according to Subhash Dhar, Founder, chairman and chief executive officer of ABS. “We are excited to have a leading cell provider like Toshiba as a key cell partner for LTO technology. Their high quality and high-performance pedigree is synergistic with ABS’ mission of providing highest quality battery solutions,” Dhar said.

“This deal, together with our other cell partnership for high energy cells with a leading Korean supplier, enhances our portfolio of energy storage solutions tailored to customer needs and optimized for application requirements,” said Ivan Menjak, Vice President of Business Development at ABS.

ABS customers now have a choice of cell chemistries, form factors, performance and cycle life, all from a single solution provider focused on high quality battery systems integration.

The battery systems will be engineered tested and validated by ABS at its Michigan technical center and produced in ABS’ Springboro, Ohio factory which includes automated laser welding of cell interconnects for industrial-grade robustness, and full production line for medium and high voltage battery pack assembly and testing.

Category: Electric Vehicles, Equipment, Featured, Fleet Maintenance, General Update, News