Bridgestone to Achieve Record Year-Over-Year Growth with More Than 7 Million Retreads Produced by Bandag Dealers in 2022

Bridgestone launched its Last Mile Tire System to accelerate adoption of retreading solutions for small- and medium-sized fleets

Bridgestone Americas is on pace to achieve its highest ever year-over-year growth in its Bandag business with a 9% increase over 2021. With the growth experienced by strategic fleet partners and the unprecedented demand in the market, the company forecasts year-end sales of Bandag retreads will reach more than 7 million units in North America and anticipates continued growth in 2023 with a $60 million investment in its Abilene, Texas retread plant to increase production capacity.

Retreading is an increasingly important solution fleets are incorporating into their tire programs that not only extends the life of their premium tire casings, but helps reduce the environmental impact of end-of-life tires, maximizes fleet uptime, and mitigates overall operating costs. Retreading also remains a critical component for fleets to unlock their ESG and sustainability goals contributing to a circular economy.

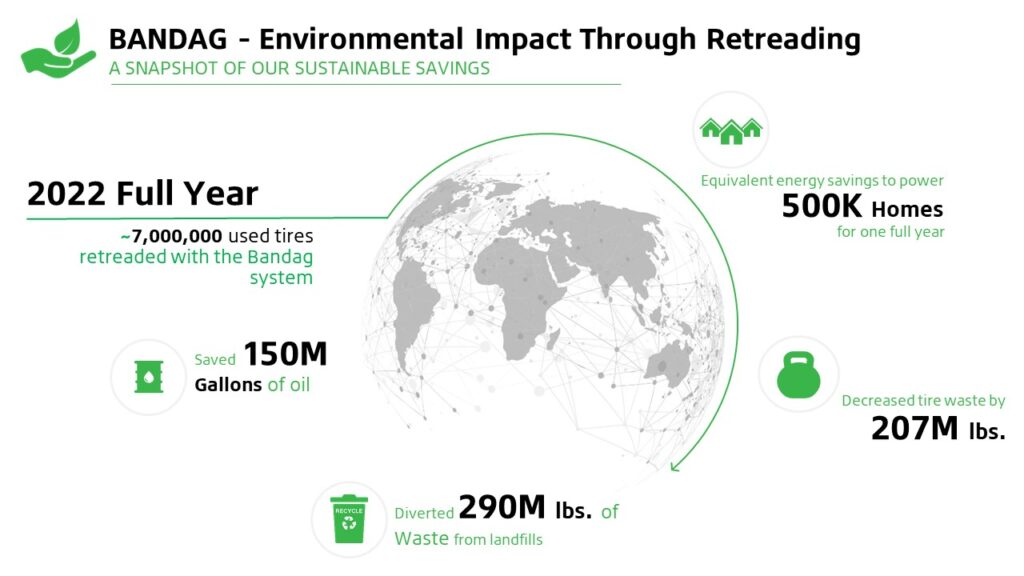

In 2022, Bandag retreads, which account for nearly half of the North American retread market, are forecast to deliver environmental benefits of approximately:

- 105 million gallons of oil saved,

- 290 million pounds of landfill waste avoided,

- 207 million pounds of tire waste avoided, and

- 5.6 billion KwH of energy saved which is the equivalent of powering 500,000 U.S. homes for a full year.

“Retreading makes more sense today than it ever has for fleets,” said Jason Roanhouse, executive director of Bandag Operations, Bridgestone Americas. “Not only does retreading deliver the same reliable performance of new tires, it helps fleets deliver on their sustainability goals while also driving bottom-line business efficiencies.”

Earlier this year, Bridgestone announced a new $60 million investment in its Bandag tread manufacturing plant in Abilene, Texas, which will add 50,000 square-feet and additional production days to meet the accelerating demand for the company’s retread products. The expansion will increase the plant’s retread output by 16% and further Bridgestone’s sustainability commitments.

Additionally, the all-new Bridgestone Last Mile Tire System (LMTS), introduced in the second half of 2022, will begin utilizing retread for small and medium-sized fleets in Q1 2023 with the goal of extending the benefits of retreading to a broader population of fleet customers. The new LMTS will allow smaller fleets operating out of the same terminal to realize greater economies of scale in their tire operations, including access to Bandag retread solutions and Bridgestone Fleet Care products. The program was launched this summer at the 2022 Route Consultant Expo, where more than 500 fleet contractors expressed interest as potential early adopters of the program.

With over 200 retread manufacturing plants in North America and a network of more than 1,100 authorized dealer commercial locations, Bandag is one of the world’s leading suppliers of retread rubber, representing nearly one in every two retreaded truck tires on North American roads today. Through Bandag’s proprietary 10-step manufacturing process, Bandag has kept an estimated 300 million tires out of the waste stream and saved over 4 billion gallons of oil over the years. Bandag’s vertical integration with Bridgestone helped to reduce supply chain challenges during the COVID-19 pandemic and beyond.

The continued expansion of Bridgestone Bandag retreading aligns with the Bridgestone E8 Commitment, which consists of 8 Bridgestone-like values starting with the letter “E” (Energy, Ecology, Efficiency, Extension, Economy, Emotion, Ease, and Empowerment) that Bridgestone commits to implement together with employees, society, partners, and customers to create a sustainable society.

Category: Equipment, Featured, Fleet Maintenance, Fuel & Oil, General Update, Green, News, Safety, Shop Stuff, Tech Talk, Wheels & Tires