Goodyear Advances Tire Development With Second Dynamic Simulator

Driving simulators allow tire models to be developed, tested and validated early in the development cycle

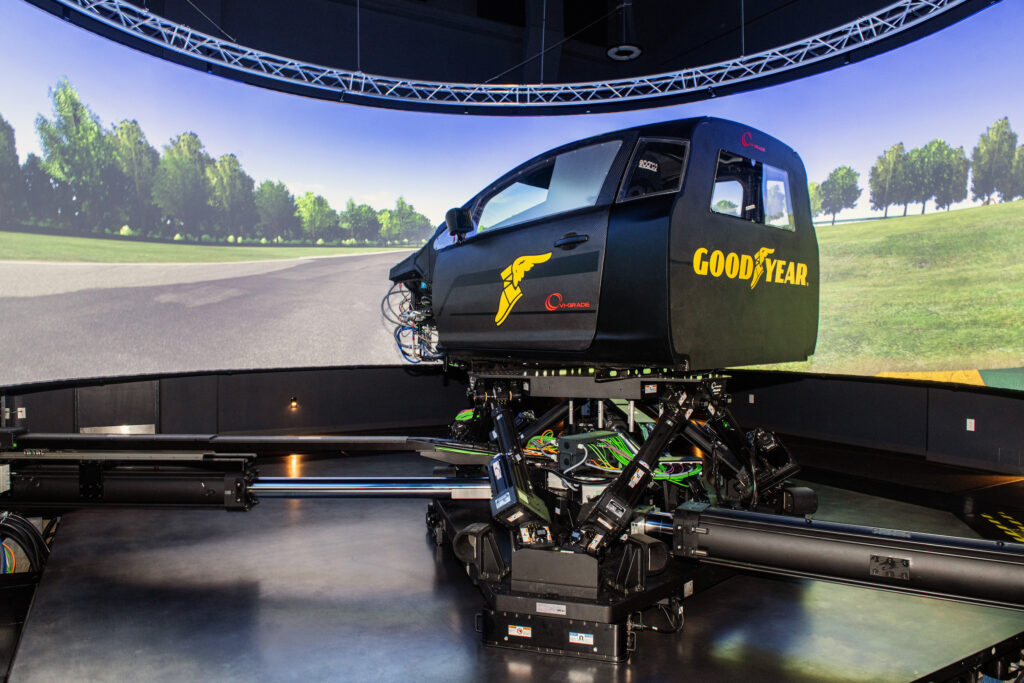

The Goodyear Tire & Rubber Company and VI-grade announced a state-of-the-art DiM250 DYNAMIC Driving Simulator will be installed at Goodyear’s Innovation Center in Colmar-Berg, Luxembourg.

In addition to strengthening Goodyear’s product development at the European site, the new driving simulator also enhances technical collaboration with its headquarters in Akron, Ohio, USA, where another DiM250 was recently put into operation. In addition, both of Goodyear’s innovation centers employ VI-grade COMPACT Simulators to complement virtual tire development processes.

Driving simulators allow tire models to be developed, tested and validated early in the development cycle, identifying the best performing tires before building a first prototype. This matches with the pace of the automotive development process, providing tire models at the right time when requested by vehicle manufacturers.

“This level of simulation capability is a clear technology leadership advantage,” said Chris Helsel, Senior Vice President and Chief Technology Officer, Goodyear. “We are always looking to improve the development process and maintain our status as the preferred supplier for our customers.”

“We are delighted to report on the adoption of a second DiM250 DYNAMIC Driving Simulator at Goodyear,” said Guido Bairati, VP Global Sales and Marketing, VI-grade. “With DiM250 and COMPACT simulators on both sides of the ocean, Goodyear is now at the forefront of virtual tire development and gains a significant competitive advantage when it comes to collaboration with automotive OEMs and accelerated product development.”

Category: Equipment, Featured, Fleet Maintenance, General Update, News, Safety, Wheels & Tires