HYZON ANNOUNCES START OF PRODUCTION OF 200kW FUEL CELL SYSTEM, MARKING A MAJOR MILESTONE IN ZERO-EMISSION TECHNOLOGY

This enables Hyzon to manufacture standardized FCSs at volume for commercial sale, further accelerating the decarbonization of heavy-duty industries

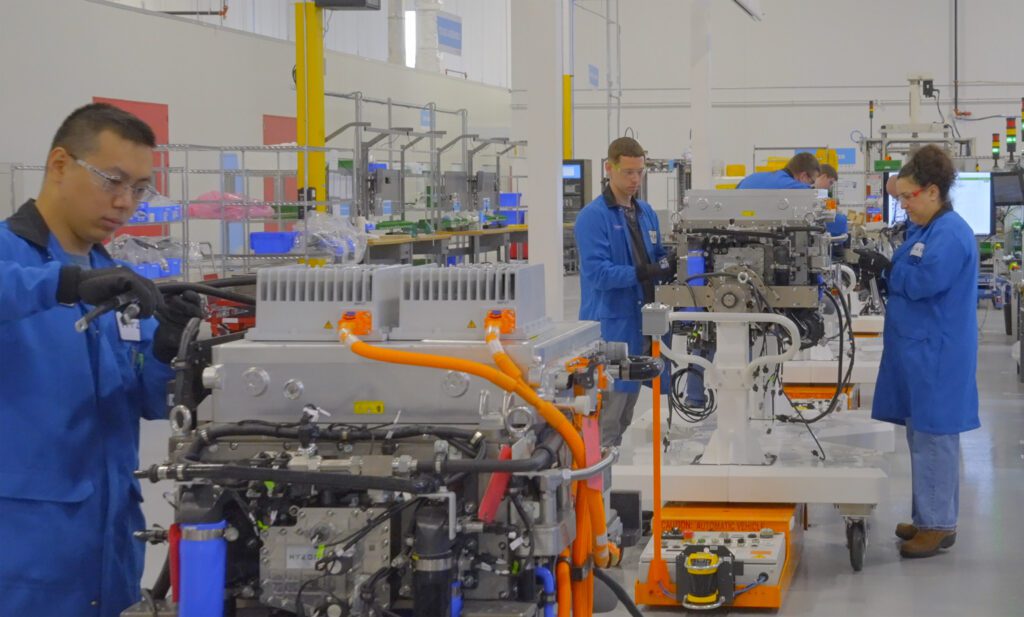

Hyzon U.S.-based, high-performance, hydrogen fuel cell system manufacturer and technology developer focused on providing zero-emission power to decarbonize the most demanding industries, announced the Start of Production (SOP) of its revolutionary single-stack 200kW Fuel Cell System (FCS). This enables Hyzon to manufacture standardized FCSs at volume for commercial sale, further accelerating the decarbonization of heavy-duty industries.

“We are excited to announce the start of production of our single-stack 200kW fuel cell system on National Hydrogen Fuel Cell Day,” said Hyzon Chief Executive Officer Parker Meeks. “Our Bolingbrook facility is one of the largest fully-integrated fuel cell systems production facilities in the United States and the only 200kW single-stack fuel system to be launched into serial production, a significant step for zero emission technology manufacturing in the US. This milestone also represents another inflection point in our mission to decarbonize heavy-duty industries. By standardizing and scaling-up production, we can provide more customers with the high-performance, zero-emission solutions they need to meet their sustainability goals. As we mark this achievement on a day that celebrates the potential of hydrogen fuel cell technology, we’re reinforcing our commitment to building a cleaner, more sustainable future.”

At SOP, all necessary conditions for full-scale manufacturing have been met, allowing Hyzon to transition from building prototypes to producing standardized units. Fully integrated manufacturing is a key element to Hyzon’s manufacturing strategy enabling rapid product development, customer responsiveness, and high power. While most other manufacturers source individual fuel cells or their components, Hyzon is integrated down to the design and production of its proprietary Membrane Electrode Assembly (MEA), the core component of a fuel cell and FCS.

“Our transition to full-scale manufacturing is a major milestone, as it allows us to move from building prototypes to producing standardized units at volume – from MEA to complete FCS,” said Hyzon Chief Technology Officer Dr. Christian Mohrdieck. “With the in-house design, development, and now manufacturing of our proprietary 7-layer MEA, we are advancing cutting-edge technology that is crucial to delivering high-performance, zero-emission solutions. This achievement underscores Hyzon’s technological leadership and our commitment to innovation in hydrogen fuel cell development and production.”

According to Chief Operating Officer Dr. Bappa Banerjee, the declaration of the SOP validates Hyzon’s ability to produce 700 fuel cell systems per year over a three-shift operation.

“The systems pass through in-line quality gates that include laser and optical vision systems and go through rigorous end-of-line tests to confirm all performance requirements are met,” Banerjee said. “All of this is done to ensure the performance of our vehicles meet or exceed the performance of diesel trucks on routes that include long stretches of steep grades as has been demonstrated during our customer trials,” he added.

Having successfully passed the ISO 9001 audit in September 2024, Hyzon expects to achieve formal ISO 9001 certification for its fuel cell manufacturing and design/R&D activities in Q4 2024, ensuring its development and production processes meet the highest international standards for quality management.

This aligns with best practices in technology and automotive product development and manufacturing. This rigorous process ensures modifications are only introduced after their maturity and contribution to performance improvement have been fully validated, reinforcing Hyzon’s commitment to delivering safe, high-quality, reliable solutions.

The 200kW FCS SOP comes on the heels of the company’s previously announced SOP of its innovative Class 8 200kW Fuel Cell Electric Truck (FCET), which was declared last month.

Hyzon also joins the nation in celebrating the tenth annual National Hydrogen and Fuel Cell Day, which commemorates the vast versatility hydrogen energy and fuel cell technologies offer the nation to reduce carbon emissions while generating domestic energy, decarbonize heavy industry, and drive economic growth and prosperity. National Hydrogen and Fuel Cell Day is observed on October 8 (10.08), in recognition of the atomic weight of hydrogen – 1.008.

Category: Electric Vehicles, Engines & Drivetrains, Equipment, Featured, Fuel & Oil, General Update, Green, News, Tech Talk, Vehicles