New Commercial Vehicle Remote Diagnostics from WABCO

WABCO (NYSE: WBC), a leading supplier of commercial vehicle technology, is introducing a remote diagnostics pilot for commercial vehicle fleets.

Here’s how it works: Rmote diagnostics monitors the technical performance of medium- and heavy-duty commercial vehicles on the road. The system enables fleet operators to detect onboard system failure modes early and optimize vehicle maintenance schedules.

WABCO’s remote diagnostics solution is the first in Europe to offer fleet operators a remote diagnostics platform that supports multiple brands of commercial vehicles and integrate it within a fleet management system (FMS). Therefore, WABCO’s solution is designed to simplify fleet management by eliminating the need to learn, operate and support various remote diagnostic systems associated with corresponding commercial vehicle brands.

WABCO’s remote diagnostics leverages synergies that link data from WABCO’s braking, stability and vehicle dynamics control systems for trucks and trailers with Transics’ fleet management platform, and WABCOWÜRTH’s diagnostic technology.

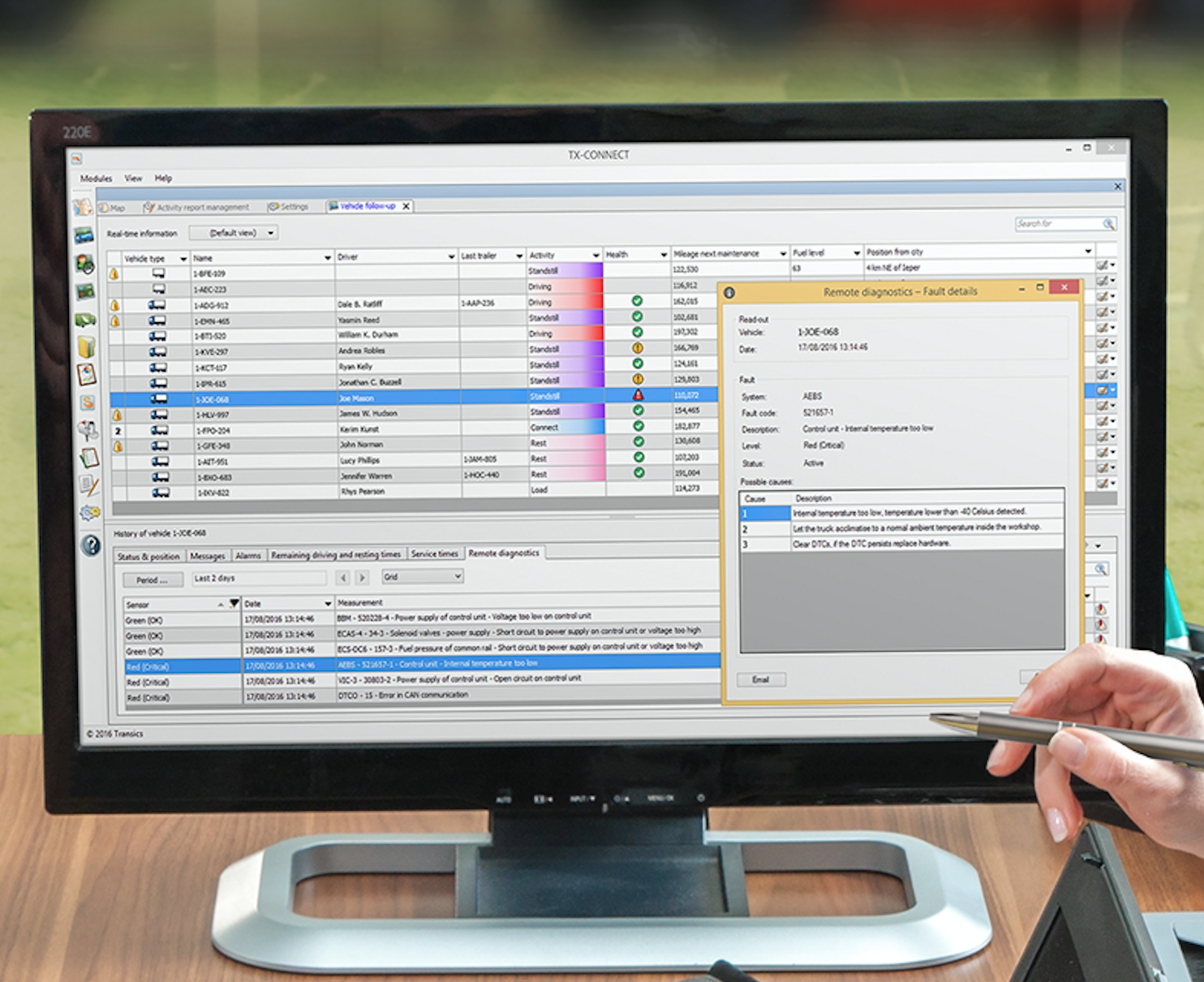

Co-developed with WABCOWÜRTH, WABCO’s remote diagnostics works with Transics TX-SKY on-board computers to monitor all electronic vehicle systems including engine control, braking, air suspension and driver assistance. Data is transmitted to Transics’ fleet management back office software platform, TX-CONNECT, which analyzes and translates it into easy-to-understand maintenance and service information within the FMS portal. Thereby, WABCO’s remote diagnostics solution helps to increase vehicle uptime by avoiding failures, reducing unplanned maintenance and optimizing service scheduling.

Remote diagnostics represents an important step in bringing vehicle connectivity closer to a future model of predictive maintenance. Under a predictive model, data collected from equipment sensors provides the foundation for calculating future performance, enabling maintenance schedules to be determined by analysis rather than by a prescribed timeline.

Predictive maintenance reduces downtime by identifying issues before failures occur, enabling efficient service scheduling, and streamlining root cause analysis.

Category: Connected Fleet News, Featured