New Solar Solutions for Service Bodies, Boom and Bucket Trucks

Go Power!, a North American provider of solar-based mobile power solutions for RV, marine, work truck and over-the-road fleet vehicles, will showcase new applications for its Solar Flex solar panels at the NAFA 2015 Institute & Expo in Orlando, Florida.

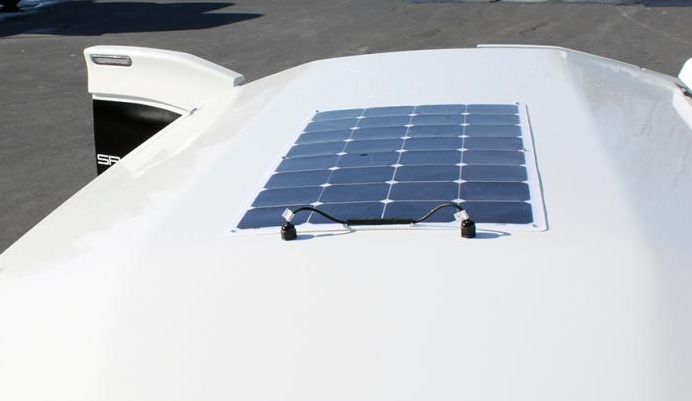

These new applications for the small, thin, flexible, ultra-high-efficiency Solar Flex panels include integration into fiberglass service bodies and designs that mount directly to boom and bucket arms.

According to Sean Brideau, from SpaceKap, “Go Power!’s Solar Flex panels have allowed us to create a standalone cap that takes only 10 minutes to install, generates its own electricity and eliminates the wire harness connection to the host vehicle’s alternator that were previously necessary.”

Before the Solar Flex solution, a truck body needing electrical service required additional labor and cabling, as well as battery isolator to preserve the vehicle’s starter battery. Vehicle-mounted workspaces often contain electronic devices that create a parasitic drain on starter and auxiliary batteries that can reduce their lifespan by as much as 50 percent each time the battery is depleted to 10 volts or below.

The Go Power! solar power generating system keeps up to four auxiliary batteries optimally charged and equipment ready to deploy, even when a vehicle has been inactive for long periods. Work trucks with boom and bucket equipment are also focusing on the company’s new 25-watt Solar Flex panel, which is small enough to mount on the lower section of a boom arm and can trickle charge dedicated batteries.

Go Power! solar arrays can be configured to generate a battery-charging capacity of between 1.5 amps per hour to 100+ amps per hour. At only three millimeters thick, Solar Flex panels are constructed using a rugged marine-grade laminate and can be affixed with fasteners through engineered eyelets or via adhesive to metal, rubber, fiberglass and plastic surfaces with parabolic bends as great as 30 degrees.

Category: Equipment, General Update